High Precision Machining

High precision molds (molded products tolerance ±0.005mm) and

high precision machining (tolerance ±0.0005mm)

About CHIMERA

Infinite skill in

“high precision”

manufacturing

High precision molds (molded products tolerance ±0.005mm)

High precision molds (molded products tolerance ±0.005mm) High precision machining (tolerance ±0.0005mm)

High precision machining (tolerance ±0.0005mm) ISO9001 JIS Q 9100 absolute quality

ISO9001 JIS Q 9100 absolute quality Challenge of cost reduction through full 24 hour production

Challenge of cost reduction through full 24 hour production Challenge of shortest delivery date (minimum 2 days) in the industry

Challenge of shortest delivery date (minimum 2 days) in the industry

Business Field

Business field

Automobile

Medical

Aerospace

Industrial Machinery

Chimera manufactures high precision molds and high precision mold components for a wide variety of industries.

This includes automotive - , medical - , aerospace, industrial machinery, and much more.

We produce items that serve the society using the industry's top-class, cutting-edge technologies and expertise from Muroran City in Hokkaido.

Products

Product

State-of-the-art Technology

State-of-the-art Technology

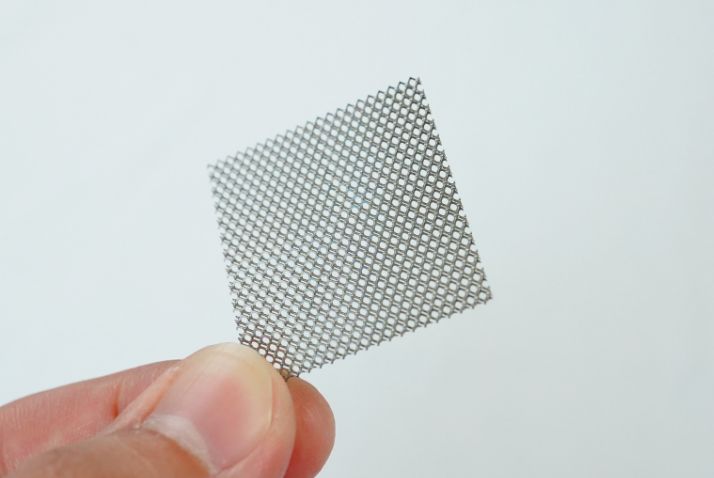

High precision molds

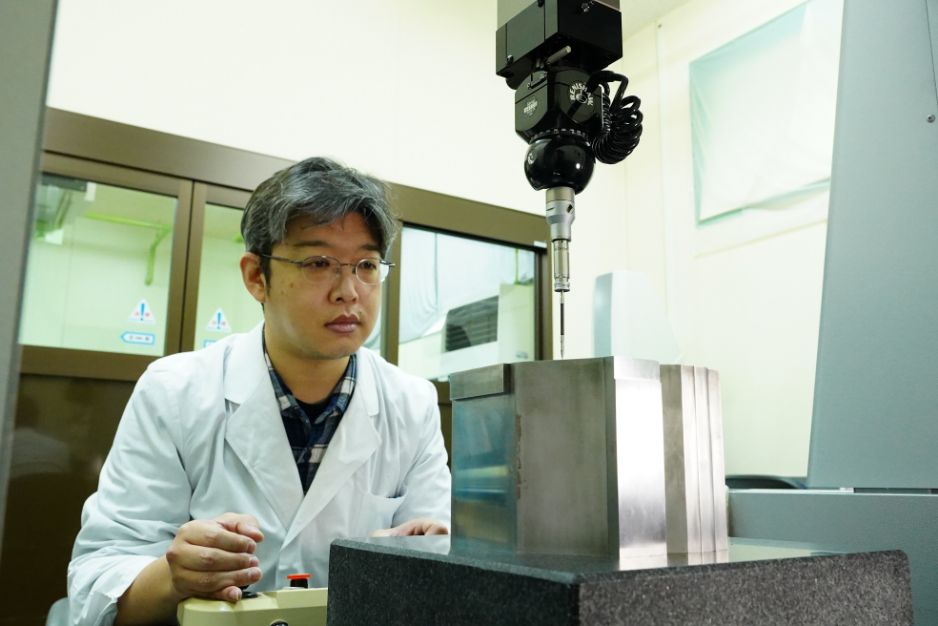

High precision mold technologies that can achieve molded product precision of 5μ. Equipped with the industry's top-level design and state-of-the-art machinery with combined effort from skillful engineers. Mold manufacturing of everything from prototype molds to mass production molds at the quality levels required for each industry.

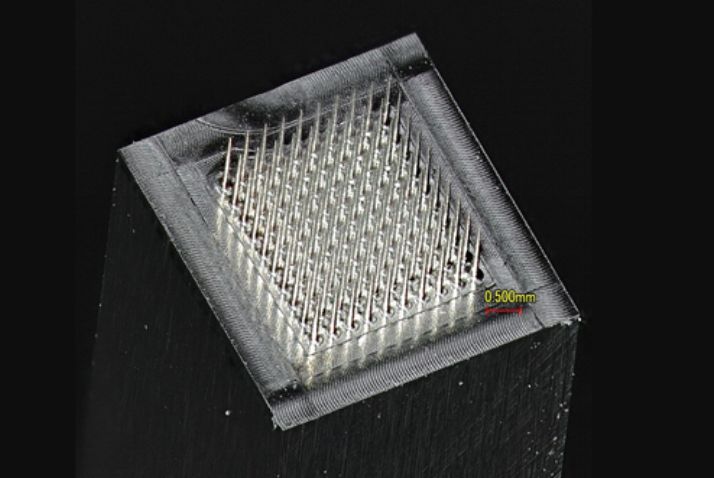

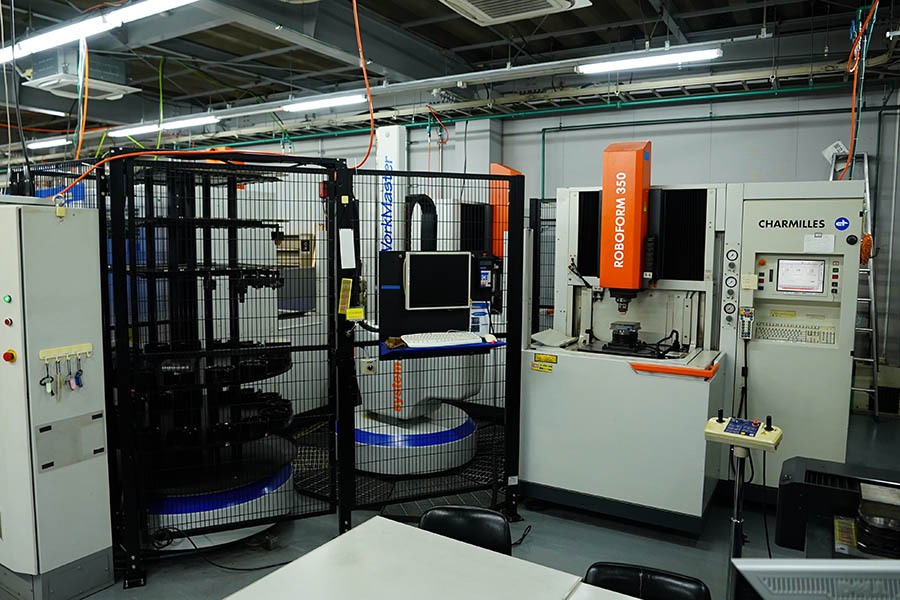

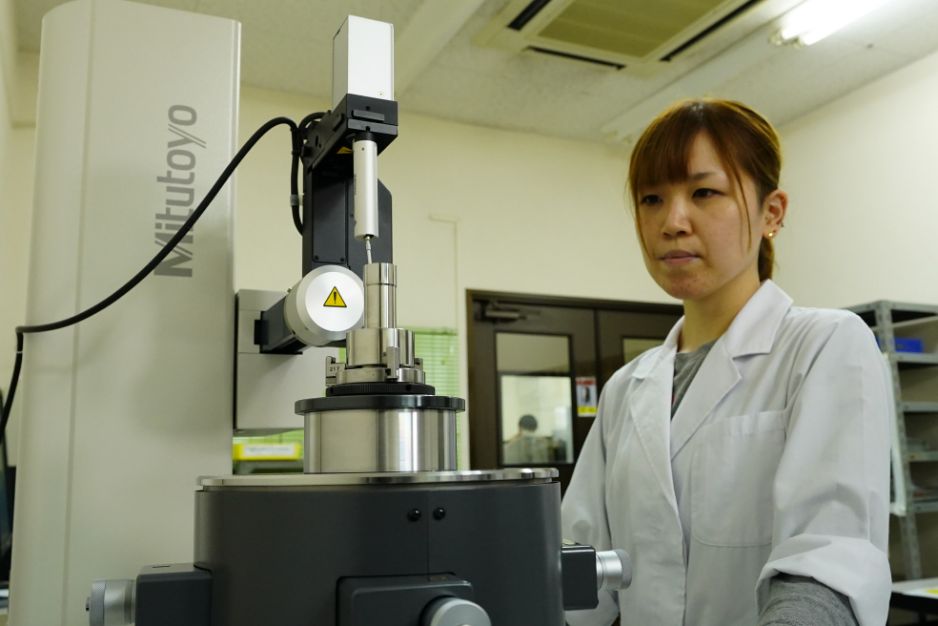

High precision machining

Chimera offers machining precision of 0.5μ (submicron). We utilize a series of technologies from CNC milling NC lathe, EDM, various types of grinders, welding, and more. We possess manufacturing capabilities up to 10,000 mold components per month.

Absolute Quality

ISO9001-2015

We acquired ISO9001 International Quality Standard certification in 2002. Chimera operates its own unique quality management system which conforms to the quality standards of numerous industries. We operate with "good ‘monozukuri’(industrial inventiveness) culture” “manufacture good things" and aim for a defect rate of 0%.

ISO14001-2015

The creation of a sustainable company and contributing to society are our company's missions. Chimera has obtained ISO14001 certification and carries out continual improvement on our production system and factory environment in an environmentally friendly manner.

JIS Q 9100

We have acquired JIS Q 9100 certification to secure more orders from the aerospace industry. We supply components for aviation and space related companies, hence components created by Chimera fly through the skies and reach as far as outer space.

Cost and Delivery date

Cost and Delivery date

90% of our customers are away from Hokkaido.

The reason why we are able to meet these customers' expected cost is because:

Minimum lead-time turnaround of 2 days for components.

Minimum lead-time of 10 days for molds.

Can we really do it that fast? Yes, we can.