Absolute Manufacturing Technology

About CHIMERA

Infinite skill in

"high precision"

manufacturing

High precision molds (molded products tolerance ±0.005mm)

High precision molds (molded products tolerance ±0.005mm) High precision machining (tolerance ±0.0005mm)

High precision machining (tolerance ±0.0005mm) ISO9001 JIS Q 9100 absolute quality

ISO9001 JIS Q 9100 absolute quality Challenge of cost reduction through 24 hour production

Challenge of cost reduction through 24 hour production Challenge of shortest delivery date (minimum 2days) in the industry

Challenge of shortest delivery date (minimum 2days) in the industry

Chimera's absolute manufacturing

capabilities

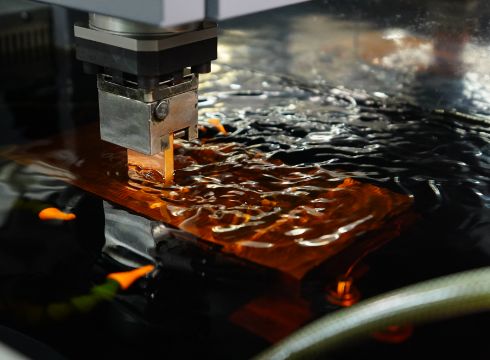

Precision mold

Precision machining

Quality

Cost

Delivery

Precision mold

One of Chimera's strengths is its high precision mold fabrication that can achieve molded product precision of 5 microns.

We provide one-stop service right from new product prototype development to the start of mass production via design using the latest 3DCAD, flow analysis, various simulations, high spec equipment as well as inclusion of proficient and skillful staffs .

We can produce prototype molds in a minimum of 2 days* and mass production molds in a minimum of 5 days*.

*Actual results

We have established reputation for mold design with a low amount of rework required at mass production and mold manufacturing technology with efficient cost saving that maintain a balance between quality and lead-time.

We also own a selection of molding machines capable of applying 30t to 100t of pressure for prototype production and can handle early-stage lot production of approximately 10,000 shots.

(Mold fabrication capability up to 150 t class)

Precision machining

We are also able to accommodate processing of individual research and development components and mold parts, and small lot mass production products (up to approximately 100 items per month) utilizing submicron level high precision processing technologies. We possess a wide range of over 100 units of equipment including state of the art CNC milling, NC lathes, WEDM, EDM, profile grinders, other various types of grinders, welders, and more.

We have also invested in robot automation and laborsaving initiatives, which allow us to provide proposals for suitable costs through the utilization of our 10,000 component per month capacity production technologies and management capabilities as well as VA proposals from our technical sales staff.

In addition, we also provide the value of "peace of mind" through our quality assurance system which conforms to the requirements of numerous industries.

Processing technology examples: 0.5μ dimension accuracy, 0.5μ geometric tolerance, 0.1μ surface roughness, thin-walled, microgroove, deep bore, microboring, mirror surface finishing, and more.

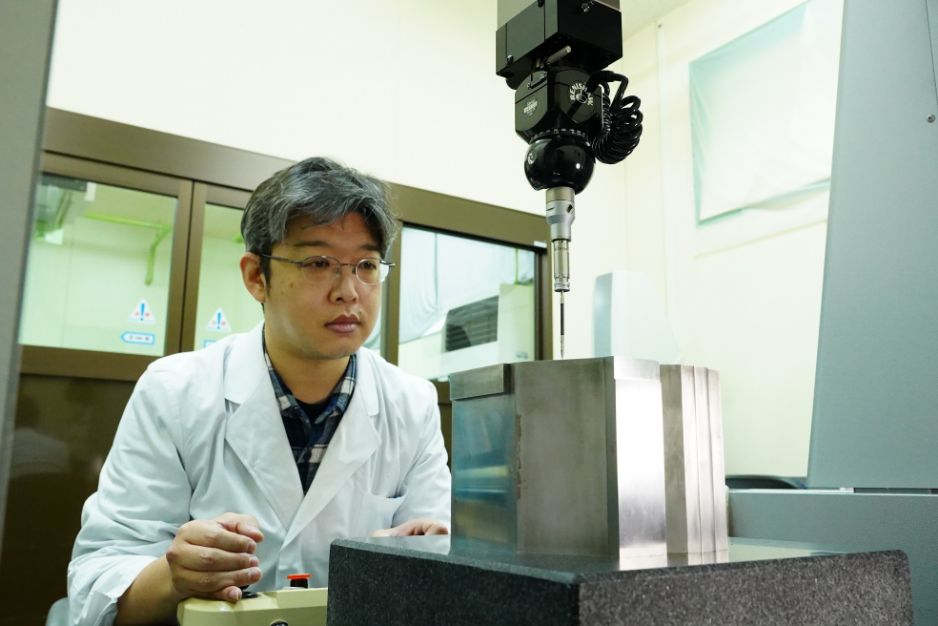

Quality

We have acquired certification in various international quality standards including ISO9001, ISO14001, JIS Q 9100, and more, and provide the quality management and quality assurance suited to the particular needs of a wide variety of industries. We can also accommodate automotive industry PPAP (Production Part Approval Process), APQP (Advanced Product Quality Planning), QC process tables, work overview, and various other quality processes as well.

We possess a variety of precision measurement equipment, including both CMM and video measurement devices, and have constructed a quality assurance system which allows us to conform to the various quality standards of different customers.

In addition, we utilize our proprietary production management system, thorough process and production management, and traceability to support manufacturing of 50 types of molds and over 10,000 components per month.

Cost

90% of our customers are from outside of Hokkaido.

See why we are still able to meet those customers' cost expectations.

Over 90% of Chimera's customers are located outside of Hokkaido. We are confident in our cost competitiveness, which allows us to still be chosen by customers despite additional shipping costs. We strive to rationalize manufacturing costs through our 24-hour production system, robot automation, laborsaving, and integrated production to reduce distribution costs between processes.

In addition, our technical sales staff provide VA/VE proposals from the initial development stages in order to provide optimal costs for everything from individual components to molds and mass production products.

Delivery

Minimum lead-time of 2 days for components.

Minimum lead-time of 10 days for molds.

Can we really do it that fast? Yes, we can.

We strive to maintain the fastest lead-time in the industry through our manufacturing capacity which allows us to produce 10,000 components and 50 types of molds a month, optimized production management, and lean, waste-free operation. We offer short lead-time and can deliver individual components and prototype molds in a minimum of 2 days* and mass production molds in a minimum of 5 days*.

*Actual results, dependent on specific conditions.

We respond to customer needs for fast lead-time through the quick responses of our technical sales staff and proposals for short delivery times. We can also accommodate video conferences using a variety of online tools.